Anybody that knows me knows that something like a paddle wheel steamboat just sitting out in the open would be something that I would not be able to pass up. I mean it would be like putting cheese or peanut butter out in front of my dog. Irrreeeessstablle.

I discovered it a while back. I knew that it was there. I knew I had to see it.

There are numerous sources online that speak of it and the service it rendered. A simple search of the name will bring them up. One of the better sources I found on it was samsace.army.mil.

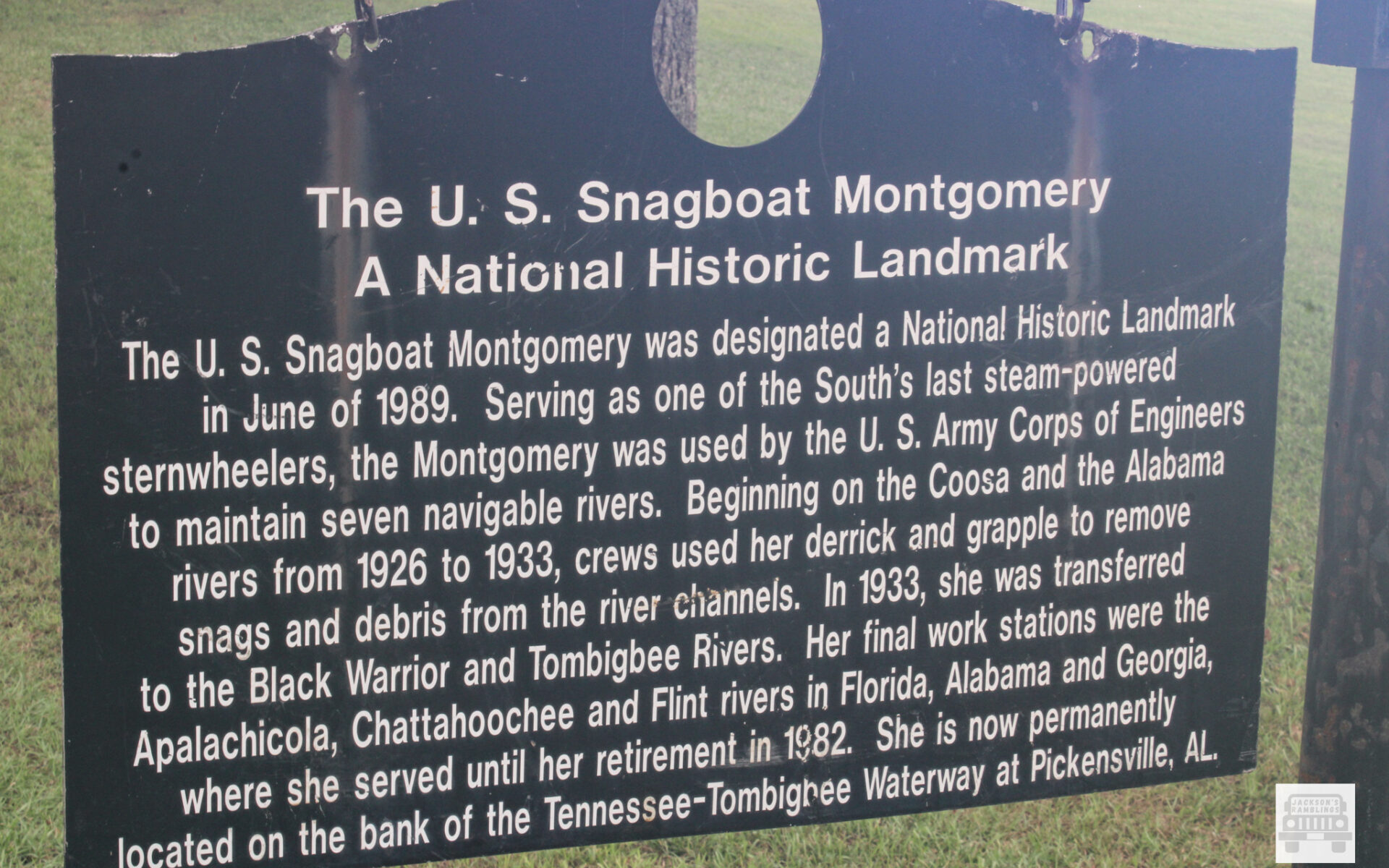

According to this site and various others it was one of the hardest working snag boats in the Southeast. It was built in 1926 at the Charleston Dry Dock and Machine Company. It was based in Montgomery till 1933. Then it moved to Tuscaloosa.

It worked the waters of the Coosa, Black Warrior and Tombigbee Rivers. The Montgomery pulled snags from these rivers until 1959. At that time she was transferred to Panama City, Florida. The Montgomery worked on the Apalachicola, Chattahoochee, and the Flint rivers starting in 1959 and continued to do so for 20 more years. Montgomery again transferred home port from Panama City to White City Florida in 1979.

The Sternwheeler has two boilers on the main deck underneath the main wheelhouse that sits high above everything for visibility. The hull is riveted steel with wooden superstructure. The Montgomery is 178 feet long and 34 feet wide. It has a 6 foot hull depth.

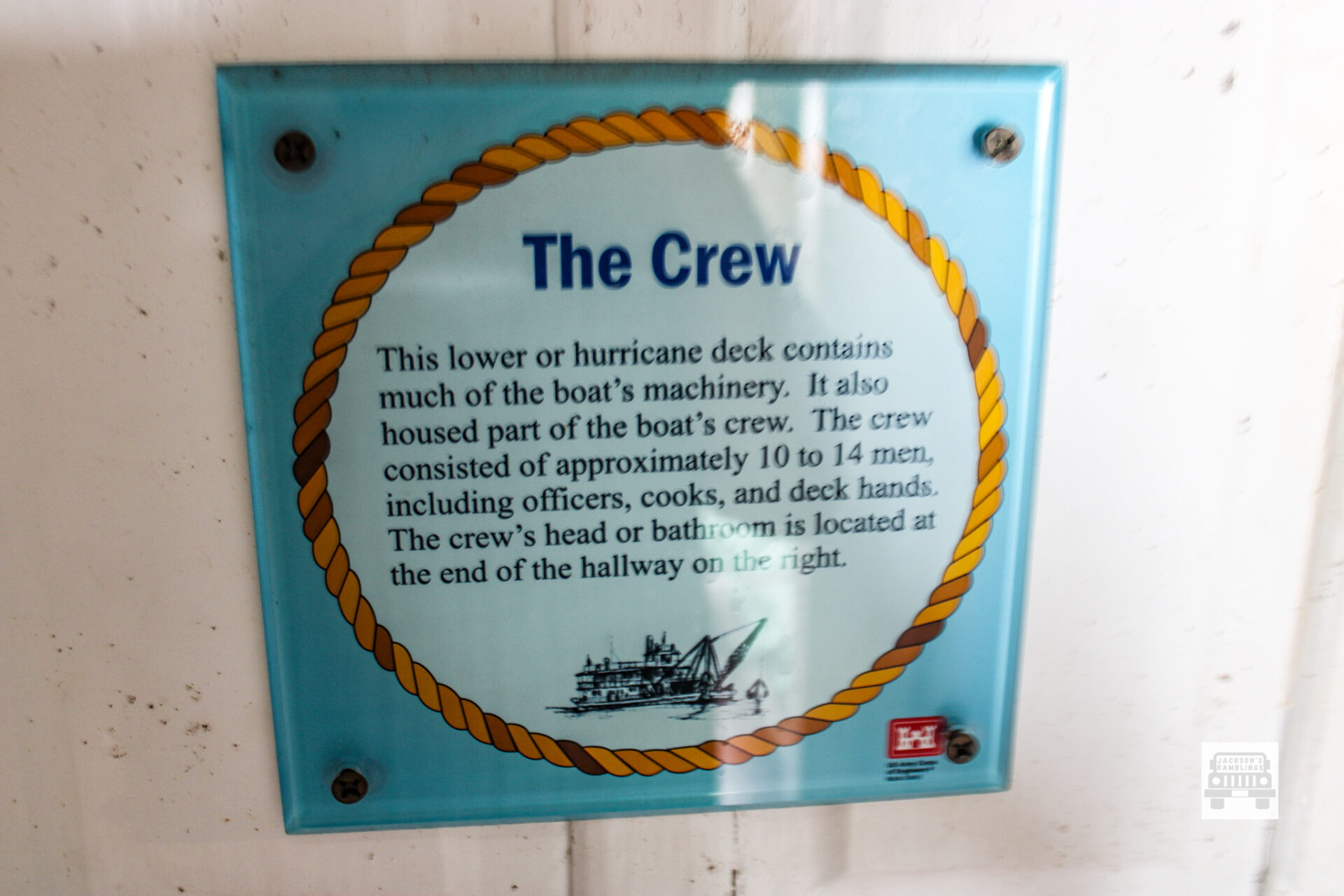

There are a total of three deck levels. The machinery of the snagging operation as well as the crew quarters and engine room are all located on the main deck. Located on the second deck is the galley, the officers’ quarters, and the office. As I stated earlier the pilot house is located on the top where the controls for the snagging and the control of the boat itself are located.

According to the information given the original boilers are still on the boat. It initially operated on coal and after WWII it was switched over to operate on diesel fuel.

From the best information I could decipher on the boat it contained a crew of 10 to 14 people. The crew included officers, cooks, and deck hands.

The officers included:

The Master, which was from my observation another name for captain. He was responsible for all of the operations and crew. His duties were to make sure that the work was accomplished but also to train the crew to operate efficiently and safely.

The Chief Engineer, was the second in command. He was responsible for all of the maintenance and repair of the entire snag boat. His main concern was the steam engines and the equipment used for day to day operation. Several men served in this position during the 56 years of operation.

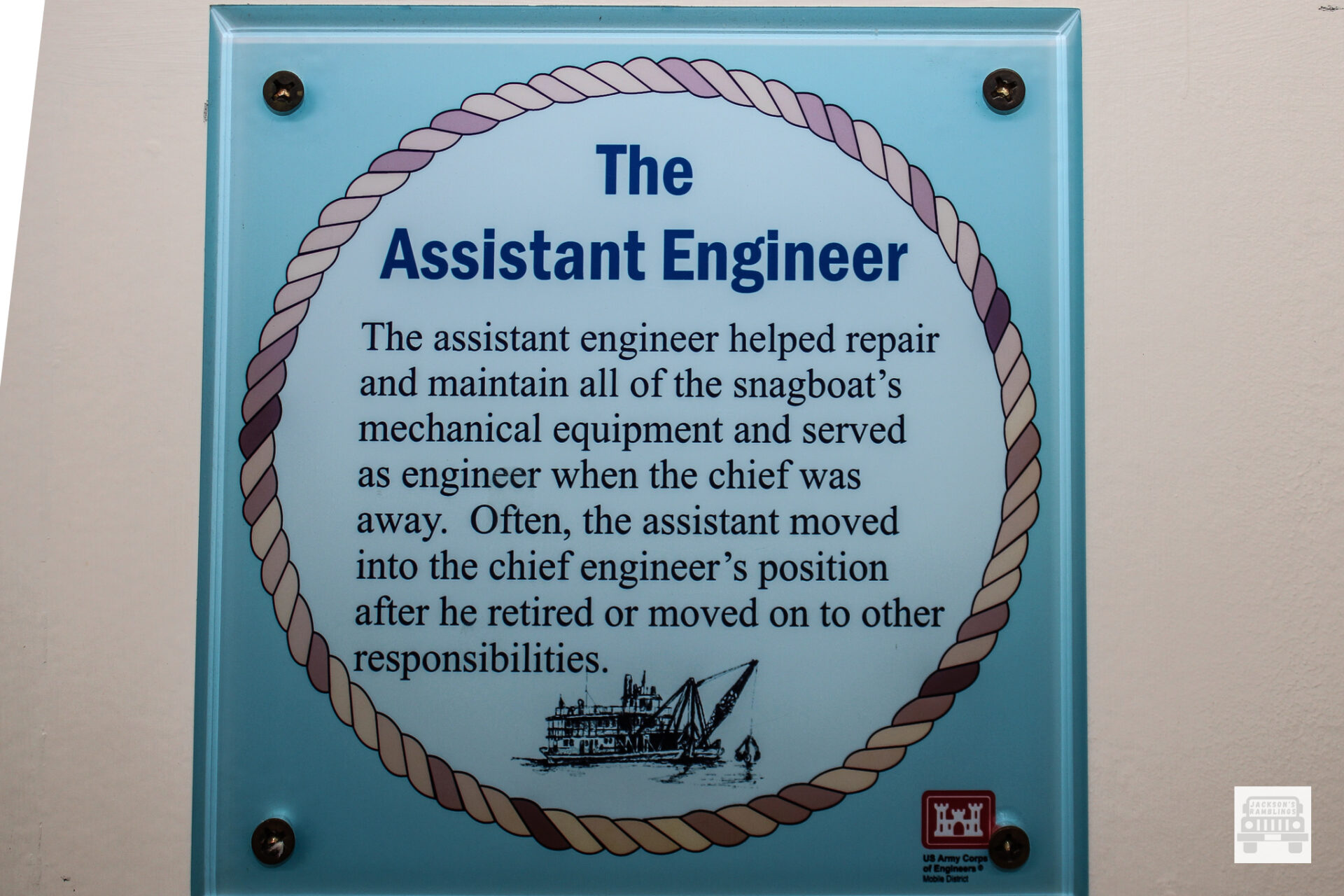

The Assistant Engineer, he helped repair and maintain all of the equipment onboard and served in the capacity of Chief when the Chief was away. Often the Assistant Engineer would move up to the position of Chief Engineer when the Chief retired or moved away.

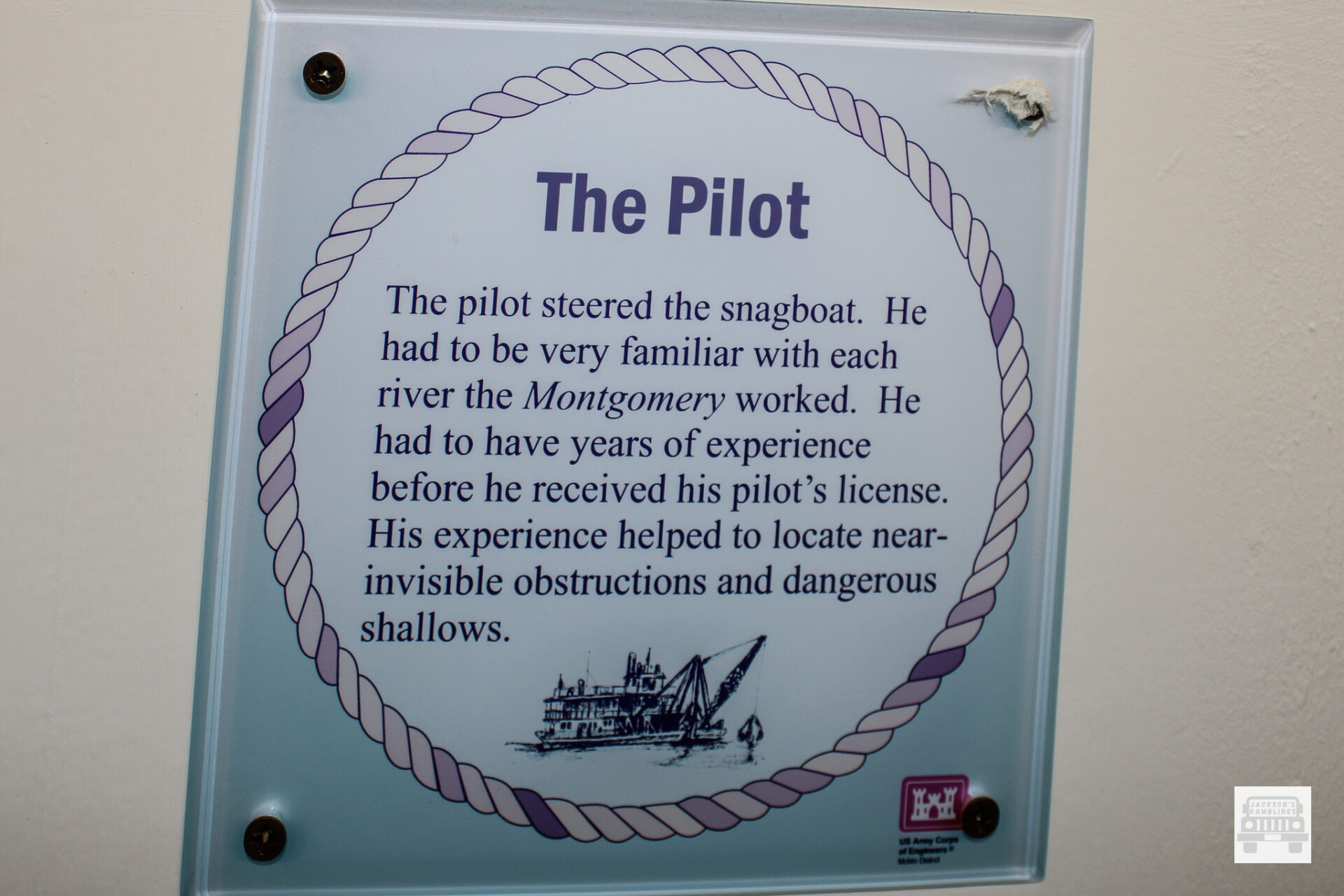

The Pilot, served to steer the snag boat as it moved about on the rivers. A Pilot had to have at least 5 years experience before he was licensed to be a Pilot.

The Operator, served to operate the machinery that worked the hoist, grapple, and so forth. He also operated from the Pilot House where he had visibility of all that was going on during the dangers and at times very tedious operation of removing snags.

Finally there were cooks and deckhands. I found no information as to how many cooks there were nor how many deck hands that were onboard at the time either.

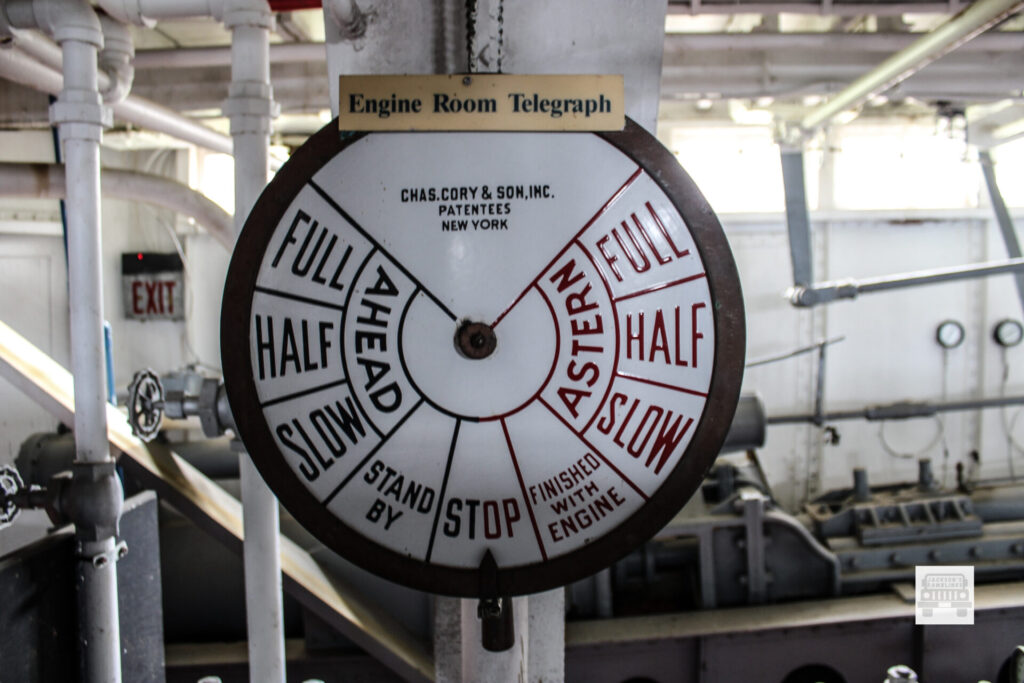

In the early days of operation the only communication from the Pilot House to the Engine Room was the onboard telegraph which was used for communication.

Viewing this magnificent piece of history gives me goose bumps just thinking about what it would have been like to live and work on this boat. In the heyday of the operation of this great boat it was a cutting-edge technology. It was a thing of beauty that was of magnificent power. One can only imagine the skills involved to operate the hoists and to pilot the boat itself.

Because of my interest in machinery and, working in a powerhouse, this gave me a sense of awe. I would have loved to be able to see it work and know exactly how it worked. I would only imagine the heat and sweat of those working to keep things running. From the site I listed above I read that there would be a barge tied alongside the Montgomery. It would work its way along pulling the snags out and dropping them on the barge. When it was loaded a tug would come along and move the barge out of the way and leave an empty barge for the Montgomery to continue its work.

One source also said that the crane could be fitted with a grapple that could be used to fish things from the bottom and load them on the barge as well.

I am so thankful that this once modern marvel did not meet its demise and end up in the scrap yard. As it sits now on dry dock however it is once again in need of some restoration as I understand that there are some rotting places in the floors in several places that have caused it to be closed to the public. Hopefully this will take place in the not too distant future so that everybody that chooses to can experience this piece of history once again.